Extreme Precision

Machining Capabilities

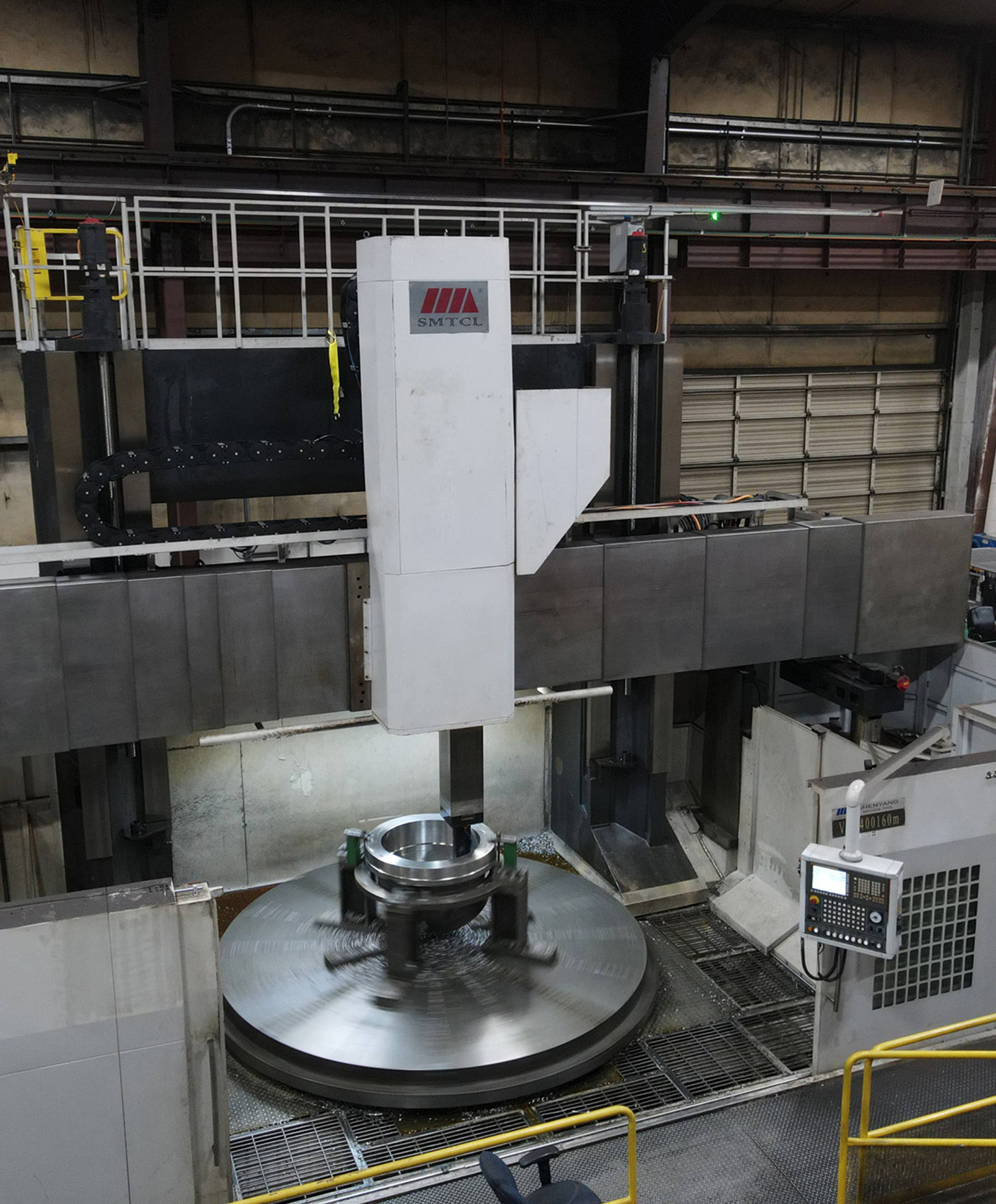

Turning – Vertical (CNC)

- Minimum OD 24 Inches

- Maximum OD 168 Inches

- Maximum Length 83 Inches

- Maximum Part Weight 70,000 LBS

Milling – Horizontal (CNC)

- Minimum OD 24 Inches

- Maximum OD 168 Inches

- Maximum Length 83 Inches

- Maximum Part Weight 70,000 LBS

Turning – Vertical (CNC)

- Maximum Length 244 Inches

- Maximum Width 100 Inches

- Maximum Height 140 Inches

- Maximum Part Weight 70,000 LBS

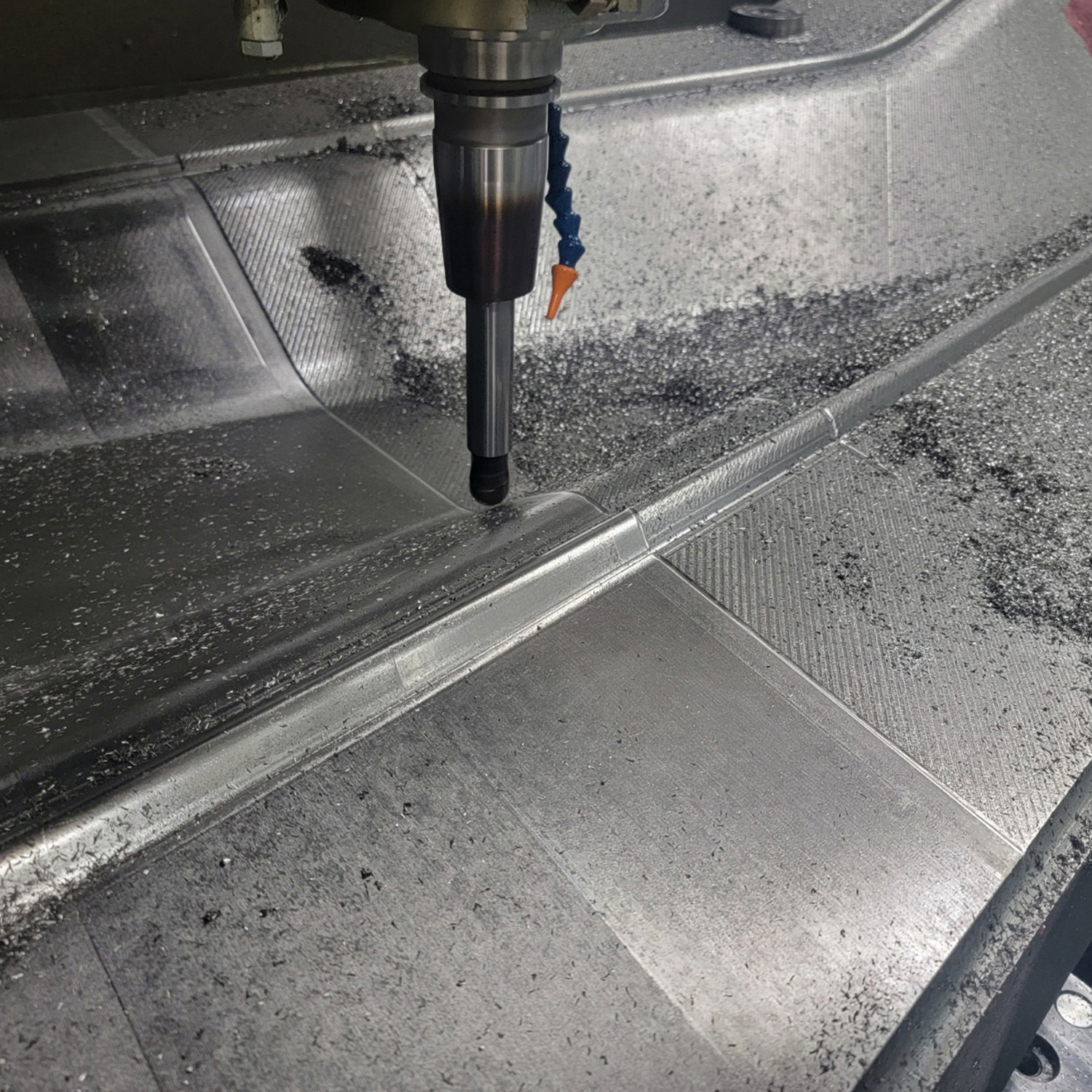

Milling – Vertical (CNC)

- Maximum Length 265 Inches

- Maximum Width 118 Inches

- Maximum Height 103 Inches

- Maximum Part Weight 70,000 LBS

Manual

- Minimum OD 24 Inches

- Maximum OD 168 Inches

- Maximum Length 83 Inches

- Maximum Part Weight 70,000 LBS