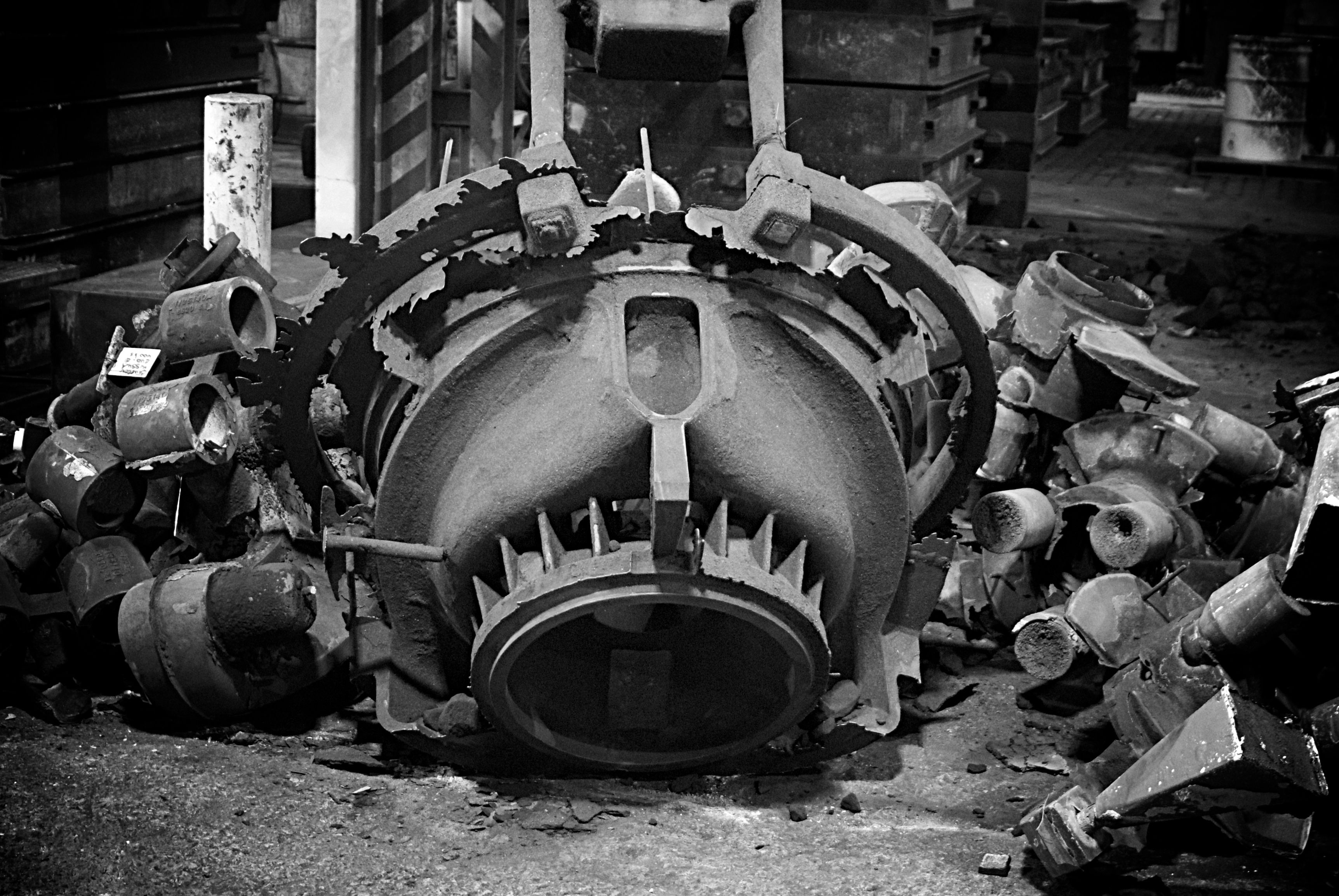

Technical Expertise and Engineering Support

- Design Optimization: Offering design assistance to optimize castings for manufacturability, performance, and cost-effectiveness.

- Material Selection: Diverse melt capabilities paired with a comprehensive range of materials, including carbon steels, alloy steels, stainless steels, duplex steels, nickel-based alloys, and specialty irons.

- Simulation and Analysis: Utilizing advanced simulation tools to predict casting performance and identify potential issues early in the design process.

Quality and Reliability:

- High-Integrity Castings: Guaranteeing castings that meet stringent quality standards and perform reliably in demanding applications.

- Material Certification: Providing comprehensive material testing and certification to ensure compliance with industry standards and customer specifications.

- Rigorous Quality Control: Implementing robust quality control processes throughout the manufacturing process, from raw material inspection to finished castings.